History

In 1947 Sidney Humphrey and Albert Law formed a partnership to make socks in Australia. They built a factory on land that had been a lemon orchard in the bush at Heathmont about 20 miles out of Melbourne

That factory still exists, although it has been considerably extended, and while the original partners have died, sockmaking continues there under the management of Albert Law’s children Rob and Elizabeth.

From the beginning, the aim of Humphrey Law & Co Pty Ltd was to provide quality and value for money. This has not changed. Today’s Humphrey Law socks are carefully made with the finest natural yarns - predominantly wool and cotton - and sold at realistic and competitive prices.

In 1989 Humphrey Law trademarked The Health Sock® made without a tight elastic top which does not restrict circulation yet does not slip down into the shoe. Other manufacturers now label some of their products as health socks but they are poor attempts to reproduce the Humphrey Law Health Sock® which is made only with healthy natural fibres, and to exacting technical requirements producing graduated knitting from the foot upwards allowing the sock to “hug” the lower leg.

Humphrey Law continues to make socks wholly in Australia. That way, they can ensure their quality in a way that is simply not possible for importers whose manufacturing is distant from them. More importantly Humphrey Law provides employment for Australians and keeps some manufacturing capacity in Australia.

Humphrey Law is the Sock Specialist – they make only socks. By concentrating and producing one thing very well they continue to produce the very best socks possible.

Making Socks

With over sixty years experience Humphrey Law are at the forefront of global sockmaking. They understand the importance of selecting the right combinations of yarns for particular styles of socks, they invest in the latest knitting technology and have the skills to implement it efficiently, and they research and trial sock designs aimed at providing ultimate foot comfort.

The journey from raw yarn to quality sock is described below with photographs of Humphrey Law’s Heathmont factory in action. You can also see how we make our socks in this video.

Yarn selection

Socks are only as good as the yarns from which they are made. So we buy the best quality yarns, for instance we purchase fine merino wool from reputable graziers and their agents who we believe are more than sensitive to animal welfare issuesAnd then it is vital to select the best yarn for any given sock. For instance, a heavyweight nylon yarn for reinforcement would be inappropriate in a fine business sock, but is vital in a worksock. Establishing the best yarn to use can involve knitting a number of socks with differing contents and subjecting them to wearing tests.

Twisting Yarns

Many socks are knitted using twisted yarns which means that different yarns are twisted together before the knitting process begins. Some of the “recipes” for twisted yarns have been developed over sixty years, and their continued use indicates they are the proven best to provide a quality sock.

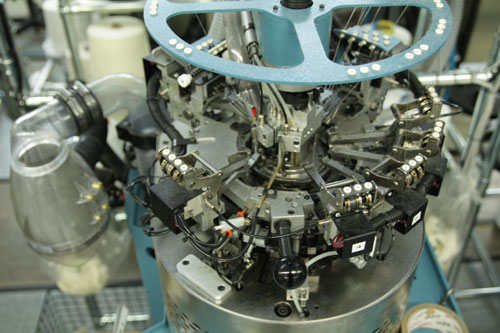

Knitting The Socks

No decent sock can be made with only one yarn, so appropriate combinations of twisted and untwisted yarns are fed into the sock knitting machine. These machines knit the sock as a tube with up to 168 stitches in the circumference. The tube has two pouches knitted in one side, one for the heel and one for the toe

Linking The Toes of The Socks

If the toes of the sock are not closed (linked) during the knitting process, the sock needs to be “linked” on a special machine.

Turning the Socks

Socks are knitted right-side out then examined for faults and turned inside out for linking. Some styles are then dyed inside out and turned after dyeing with a vacuum device.

Dyeing the Socks

Humphrey Law dyes all its socks in-house. Stock of undyed (greige) socks is maintained for popular styles to allow customers’ requests for additional supplies of particular coloured socks to be quickly supplied. Waste products from the dyeing process are disposed of according to local water authority standards.

Pressing the Socks

After the dyeing process the socks are pressed.

Quality Control

Every pair of Humphrey Law socks is individually checked in the grading room to ensure they have no defects and then paired

Labelling The Socks

Pressed and graded pairs of socks are then labelled appropriately.

Despatching The Socks

Customer orders are picked, packed and despatched promptly. Packing is designed to keep the socks in the same condition as they leave the factory. Humphrey Law’s despatch operation and delivery performance is ranked at the top level by local department stores.

Our Environmental Credentials

We were practicing “Environmentally Sensitive” policies long before that phrase became popular. We have always recycled our cardboard and plastic waste, often re-using cardboard boxes and cones internally before recycling.

When we re-furbished our knitting room in 2004, we installed a low energy climate control system that works without the need for refrigerated air-conditioning, and which led to raw material waste being greatly reduced as the humidity in the room is accurately controlled. We now have no heating costs in that room in winter because of that system, double glazing, extra insulation and the recycling of waste heat into that room from another process. This environmentally sensitive project has cut energy costs, reduced waste, improved product quality and assured accuracy of sock sizing.

Moreover, we have recently:

• installed a new state-of–the-art dyeing machine which uses less water, uses less energy, uses less chemicals and reduces our waste

• replaced fluorescent lighting tubes with LED tubes throughout our factory, reducing energy use.

• recycled and repaired the existing fluorescent fittings and removed their ballasts to use for the new LED tubes. The removal of the ballasts improved our Power Factor. (An improved Power Factor means our energy supplier can supply more customers with the same cable size). Our lighting energy use has decreased by 70% as a result of these two measures

• installed solar panels to provide hot water for all our dyeing machines.